Enabling fashion brands to track

second lives of clothes

What is the Problem?

When the European Union introduced the Ecodesign for Sustainable Products Regulation (ESPR), it marked a turning point for the fashion industry. Suddenly, brands weren't just responsible for creating and selling clothes—they were accountable for what happened to them after they left the store.

At the heart of this regulation was the Digital Product Passport: a digital record that follows a garment throughout its lifecycle—from manufacturing and use, to repair, donate, resale, and recycling. The goal? Total transparency and circularity. But with that came a pressing question for many fashion brands:

How do we actually track all of that

especially after the product is sold?

Business goals of

the customer

Nordic fashion brands like Kappahl, Marimekko and their repair studio network partnered with TrusTrace to design a scalable, easy-to-use system that powers DPP implementation while improving circular fashion operations.

Support Circular Fashion Initiatives

Track and visualize actions like repair, resale, donation, and recycling.

Improve Product Development

Feed real-world claims and repair data back to design and sourcing teams.

Streamline the Secondhand Economy

Optimize resale readiness, inventory visibility, and pricing.

Research team conducting on-site interviews with brand stakeholders in Örebro, Sweden

Key user problems and

questions posed to users

We conducted on-site research with brand stakeholders and repair studio teams in Örebro, Sweden to understand their workflows and challenges. Through targeted interviews, we explored pain points around data entry, traceability, and team collaboration—insights that directly informed our design decisions.

- How do you currently log information about incoming garments?

- What's the most time-consuming part of entering data?

- Can you easily access a garment's full journey—from claim to resale?

- What kind of information would you like to see about a product's past?

- Do you ever experience delays or mismatches in data between teams?

- What kind of updates or info do you wish you received from other departments?

- How do you identify if a product or fabric has recurring issues?

- Would alerts or trend visualizations help in decision-making?

Design Approach

We began by mapping the end-to-end flow of a garment's "second life," from arrival at the repair studio to resale or recycling. This helped define:

Who needs visibility

What information feeds into the DPP

We co-created a system that balanced regulatory needs, real-world operations, and end-user simplicity.

Collaborative design workshop with stakeholders exploring digital tracking solutions

- We worked closely with stakeholders across departments—brand HQ, store teams, repair studios, and recycling partners—to co-create a detailed map of the garment lifecycle.

- The process involved multiple rounds of iteration, where we gathered feedback, tested assumptions, and refined the workflow based on real operational constraints.

Comprehensive workflow mapping showing the end-to-end garment lifecycle with stakeholder touchpoints, activities, and data collection points

- We created extensive wireframes to explore and validate key workflows—from garment intake to repair tracking and resale preparation.

- Through multiple iterations, we collaborated closely with both brand stakeholders and repair studio users, incorporating their feedback at every stage.

- This collaborative approach ensured the designs were practical, intuitive, and aligned with real-world operations.

- Our initial solution to let users start the physical sorting process by creating organized garment batches—the first step in tracking a garment's second life.

- Recommended solution for users to digitally input the number of sorted garments while simultaneously performing the physical process.

- A page displaying the complete history, details of garments that have been repaired, washed, and ironed, along with the associated costs.

Usability Testing &

Iteration

We conducted a virtual usability testing session with users from the repair studio, using clickable prototypes. The goal was to validate whether the batch creation and garment processing flows aligned with their real-world workflows.

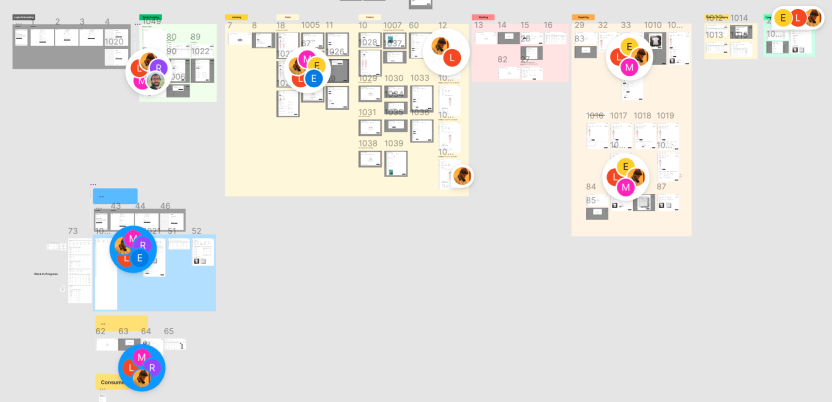

Usability testing heat map showing participant interactions and feedback points across different sections of the interface

Layout Optimization

On the sorting page, users mentioned that scrolling was inconvenient since they often add data while physically sorting garments. This led us to restructure the layout into a more compact, non-scrollable format for quicker input.

Step-by-Step Visualization

Users appreciated the step-by-step visual breakdown in the completed garments view, saying it helped them clearly track each stage a garment went through.

Visual Documentation

Adding before and after photos of repaired garments was seen as helpful for quality assurance and audit trails.

Developer Collaboration &

Feasibility

To ensure technical feasibility and alignment with development timelines, we conducted a detailed design walkthrough with the engineering team early in the process. This helped us identify constraints, prioritize features, and co-define what was realistic for the MVP vs.future releases.

Cross-functional collaboration session where designers and developers worked together to evaluate technical feasibility of the garment batch creation interface

Data Storage & Access Method

- Our original design included saving garment lifecycle data directly onto NFC tags.

- Due to hardware and time constraints, we agreed that for the initial release, data would be stored in the web platform.

- QR Codes would be used for scanning and linking instead of NFC.

- NFC integration was deferred to a future version.

Image Upload Limitations

- While the design supported before/after photo uploads for each garment, initial implementation was limited to single image upload per stage.

- This limitation was due to backend storage constraints.

- Batch photo uploads were scoped for later releases.

PLM Integration Strategy

- Connecting directly to the PLM system in real-time was outside the current sprint scope.

- We agreed to manually sync certain data fields via CSV uploads or APIs in the background for now.

- Real-time sync was planned for post-MVP implementation.

Design Delivery

- Optimized for Tablets: Designed for use on tablets during physical garment sorting at repair studios.

- Touch-Friendly UI: Large, easily tappable elements improve accessibility and reduce input errors—aligned with Fitts's Law.

- Responsive Layout: Fully adaptable across web, mobile, and tablet for operational flexibility.

- Quick Input Controls: Plus/minus buttons enable fast garment categorization with minimal typing.

- Sequential Process Tracker: Shows each step in the garment journey—Product ID, Wash, Repair, Ship, Costing—keeping teams aligned on progress.

- Rich Product Metadata: Displays all critical attributes like material composition, size, style, color, and season, sourced from PLM or manually entered.

- Condition & Repair Needs: Captures flaws identified at the take-back facility, including structured and free-text inputs for accuracy.

- QR Code-Driven Access: Brand users scan the garment’s QR Code to instantly retrieve its full repair history, condition, and cost breakdown.

- Complete Process History: Tracks each step from intake to repair, showing cost per stage and visual progress completion for transparency and accountability.

- Flaw & Repair Breakdown: Documents the type and location of flaws, repair method, and material usage—essential for resale quality validation.

- Material & Cost Details: Lists all repair materials used (e.g., thread, interfacing, zippers) and associated costs for resale pricing and profitability analysis.

- Editable Resale Price Field: Suggested resale price is auto-generated, but brand users can override and assign custom pricing based on garment condition.

Business Impact and Usability Wins

3000+ Garments

tagged with QR/NFC and resold with full traceability by Q1 2024

3-4

new pilots

with other scandinavian brands

Expansion to UK

underway for 2025

Reduced Mistakes by 40%

Label scanning helped studio staff reduce data entry mistakes by over 40% during testing.

Improved task completion by 30%

A guided batch flow allowed users to quickly assign garments to the correct lifecycle step, improving task completion time by 30%.

Improved Dashboards

dashboards gave brand HQ, repair studios, and store staff visibility into inventory, costs, and garment flow.